Find out about our manufacturing steps

At Cygnes, we firmly believe that quality begins with careful and ethical manufacturing. That's why our tights are proudly designed in France , through a meticulous process that guarantees comfort, durability, and aesthetics. Discover with us the eight key stages in the manufacturing of our tights, a true journey of know-how !

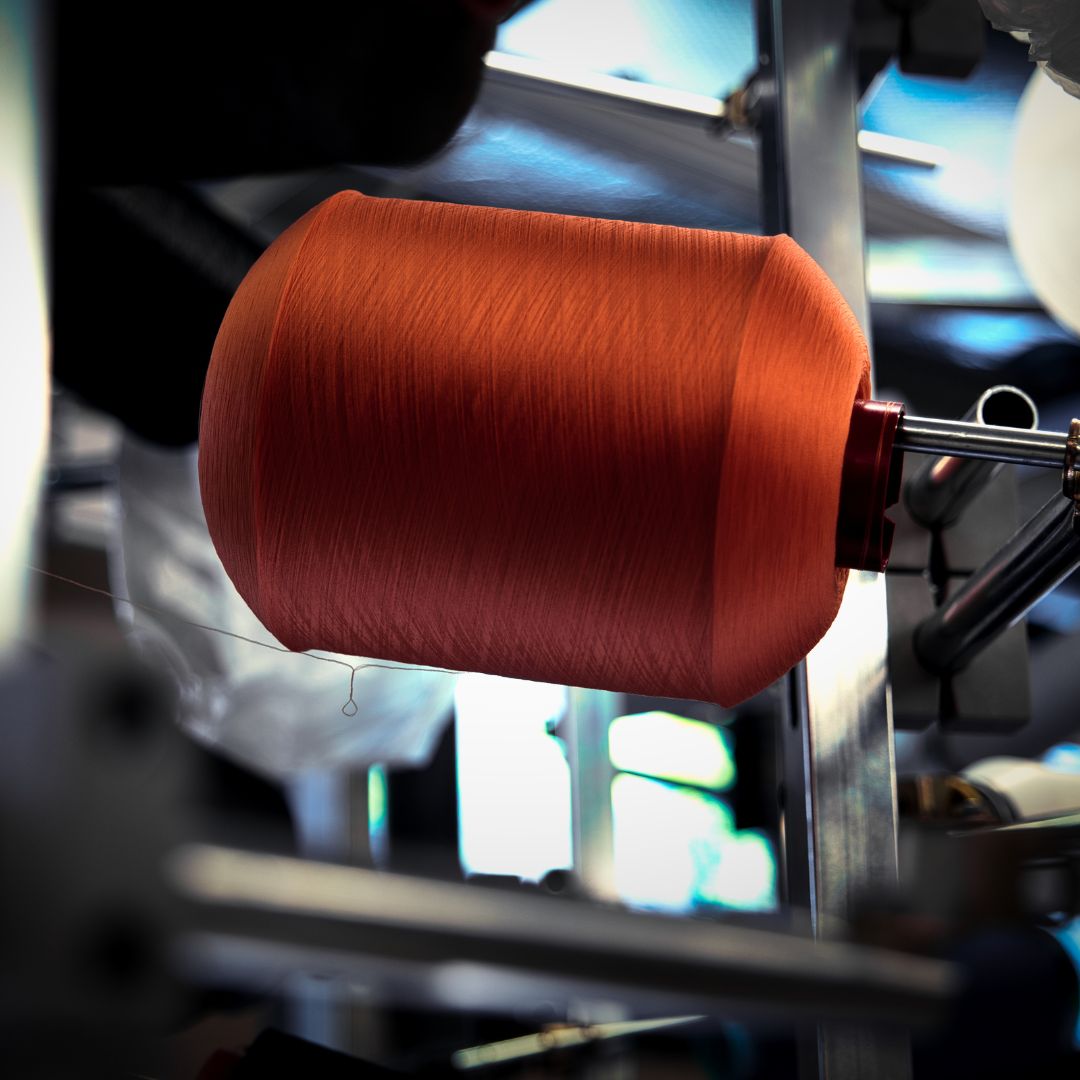

1. Spinning

It all starts with the spinning mill, where our yarns are carefully produced. Our spinners process them to strengthen them (by coating the yarns or treating them in a way that improves their strength), ensuring the robustness required for our tights. This first step, carried out in France, is essential to guaranteeing the quality of our products from the start.

2. Knitting

Once the yarns are ready, comes the knitting stage, carried out by our partner, a tights manufacturer in France. Here, the yarns are transformed into tubes : one tube = one leg. The waistband and foot reinforcement are also knitted at this stage, which contributes to unparalleled comfort.

3. Round Seam

The tubes thus formed are then closed at the feet by our craftsmen, guaranteeing a precise and careful assembly. Here we carry out what is called a “round seam”, which is done manually to ensure maximum resistance . This crucial step is always carried out in France, highlighting our commitment to excellence.

4. Coupe Monté

Our tubes are then manually assembled using a cotton gusset (to add space or improve the shape) at the crotch. The flat seam used at this stage ensures not only greater strength but also optimal comfort. Here, once again, we collaborate with our local partner to guarantee the quality of each piece.

5. Dyeing the tights

Tights come to life during the dyeing process. We immerse a large quantity of tights in dye baths to maximize this phase. Once the dyeing is complete, the water is treated to meet our environmental commitment.

6. Forming

The magic continues with the shaping process. Our tights are steam-ironed to dry them and set the dye , giving them an impeccable finish. This step, crucial for the final quality, always takes place on French soil.

7. Quality Control and Packaging

The final step is quality control and packaging . Each pair of tights is carefully inspected, folded, and packaged in our offices, ensuring that only the best products reach our customers. This commitment to quality and service is reflected in every pair of Cygnes tights.

A Commitment to Quality and Local

Every step in the manufacturing of our tights is carefully considered, highlighting our commitment to quality French craftsmanship. We are proud to work with local partners and contribute to a more responsible and ethical economy. By choosing Cygnes, you are choosing tights that combine style, comfort, and respect for the environment.

You can find all our manufacturing steps explained in video on Youtube:

“Discover our collections and choose chic and quality, designed in France, just for you.”

Take the opportunity to fall for our new 30D Revolution tights:

Fall for your Swans product now!

By choosing Cygnes , you are choosing responsible, ethical, and sustainable fashion. Our tights combine comfort, style, and quality, while being part of an environmentally friendly approach. Don't hesitate to adopt Cygnes tights and join the community of those who want to consume differently: